PRISMS / BOARDS PROCESSING

MULTIPLE RIPSAW AND CROSSCUTTING

Code equipment: MULTIRIPSAW - CROSS-CUT EN

Short description

Multi-ripsaw machines to proceed the prisms / beams with different thickness (40 - 250/320) mm and length. Multi-ripsaws with one shaft (blade) and with two shafts (blades).

The most famous and recognizable in the world Multi-ripsaw of A. Costa Brand trace their history from 1922. The main distinctive features of the A. Costa machines always have been their constant high reliability, easy and friendly in operation and maintenance, the highest quality of products and excellent economic efficiency.

A. Costa multi-ripsaw machines historically are the symbol of reliability and high quality in woodworking equipment.

Spread range of multi-ripsaw machines is produced by A.Costa Righi to proceed the prisms / beams, for use as separate machines and as the parts of Sawmill Lines with standard configutation.

A. Costa Righi in the production program has the following Automatic multi-ripsaw machines to proceed the prisms / beams:

Double-shaft multi-ripsaws for longitudinal sawing of prisms / beams with large and medium thickness:

Double-shaft multi-ripsaws for longitudinal sawing of prisms / beams with large and medium thickness:

LEONE/2 - with sawing thickness till 250 mm;

FALCONNE/2 - with sawing thickness till 220 mm;

ML 2-420 - with a sawing thickness till 180 mm.

Also, for longitudinal sawing of prisms / beams with medium and small thickness One-shaft multi-ripsaws manufactured:

ML 1-420 - with a sawing thickness till 115 mm;

RI 500 - with sawing thickness till 140 mm;

RI 150 - with a sawing thickness till 150 mm.

The presented multi-saw machines have models with movable (positioned) saws (groups of saws). The number of movable saws (groups of saws) can be up to three (1-2-3).

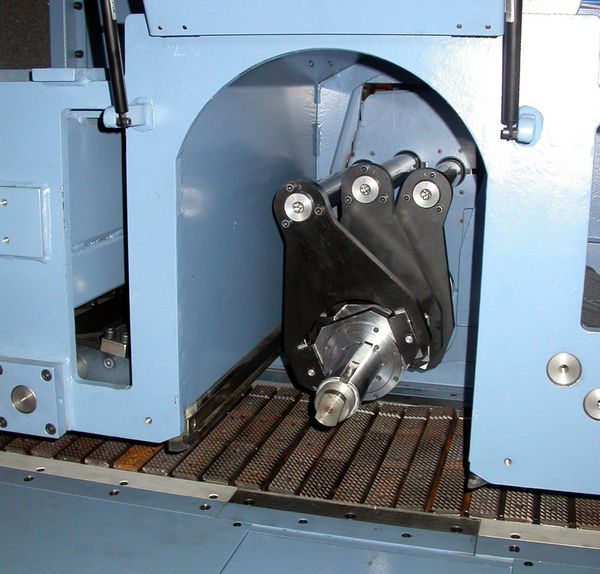

Automatic double blades cross-cutting machines are produced for transversal cross-cutting of prisms / beams into pieces:

MAXI-CUT - with two movable "vertically falldown and jumping-up" saw blades, cutting thickness: 38-180 mm and the length of pieces may be cut out: 700 - 4000 mm;

BETA - with two movable "horizontally going-in and going-out" saw blades, catting thicknes: 40-200 mm and the length of the cutting-out pieces: 600-3200 mm..