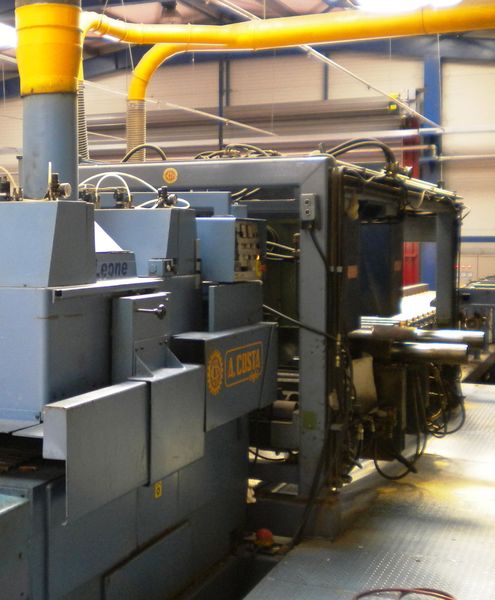

PALLET LINE A.Costa - TPL

Short description

Sawmill Line TPL Pallet Line to produce the wooden precise elements for pallets production - PALLET / PACKAGING LINES. This type of Lines historically take the special, most popular place in A.Costa sawmill equipment production program. And also historically A.Costa is the the main world brand in woodworking industry, specializing in this area. Some types of machines in A.Costa production program are developed and produced strictly for need of industrial pallet boards production.

TPL Pallet Line proceed in follow way.

Automatic prisms feeding system with reading and turning devices put coming prism into maximum flat (wide) position before to be processed deliver coming prisms by Automatic double cross-cutting machine - MAXI-CUT. Machine MAXI-CUT equipped by self-centering device. This device with two hydraulically moving "hands" put the initial part of incoming prism into maximum linear position and cut-out the initial part of coming prism by two "flying" sawblades. These sawblades in guillotine way fall down and cut the prism in demanded length.

In the same time measuring system read the effective width of cutting pieces and put the installed after MAXI-CUT Canter CANTATA into demanded position. Cutting pieces go through Canter, and Canter milling out the waste parts from both sides of proceeding piece.

And piece going onto the outfeeding-infeeding conveyor, where the processing piece by hydraulically moving "hand" is pushed and pressed to right side sliding-chain, and to be fixed additionally from the top - strictly pass through Double shaft multiripsaw LEONE/2.

By Double shaft multiripsaw LEONE/2 coming piece is cutting into pallet boards of demanded thickness.

After LEONE/2 are installed the output system and Automatic Stacking system for produced pallet boards.