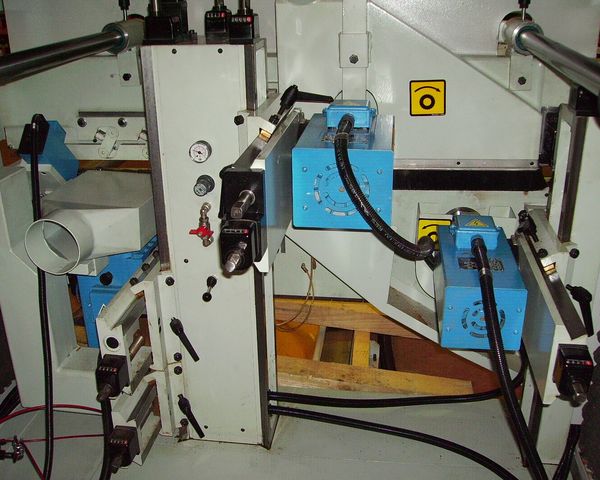

Double end tenoner / profiling machine ASTRA

Code equipment: Astra

Short description

Double end tenoner / profiling automats ASTRA (ASTRA/PA4 or ASTRA/PA6) to produce all the transversal profiling operations in massive parquet production.

Double end automatic tenoner ASTRA (ASTRA/PA4 or ASTRA/PA6) - complete automat to produce all the transversal operations in massive (solid wood) parquet production. Machine ASTRA usually used as second, transversal machine in all the world known A.Costa B3 Parquet Lines. Machine ASTRA is the common known symbol of quality and highest reliability of A.Costa trade mark parquet equipment.

Depend of the Client needs machine can have four (for ASTRA/PA4) or six (for ASTRA/PA6) working units.

Mod. ASTRA/PA6 has: three working units at the left and three working units at the right sides of machine.

Machines ASTRA has the patented special new version of top pressure system with steel claws (nails), without belt for pieces feeding into processing. This feeding system, installed at the both sides if machine, very strong and with 100% accuracy by special "feeding claws" keep and pass the pieces through all working units. Exact this patented feeding system establish the highest quality of production.

Left sides of ASTRA machines bed plates are fixed, and the right sides are movable. The replacement of the right side is produced by special screw ball-bearing motorized mechanism with its own automatic lubrification system.

Main technical characters of ASTRA machines:

- min-max length of proceeding pieces: 200-1700(2500, 3200) mm;

- max width of proceeding pieces: 150(250) mm;

- max thickness of proceeding pieces: 85 mm;

- continuously adjustable feeding speed: 8-32 m/min.

Depend of the Client needs machine can have four (for ASTRA/PA4) or six (for ASTRA/PA6) working units.

Mod. ASTRA/PA6 has: three working units at the left and three working units at the right sides of machine.

Machines ASTRA has the patented special new version of top pressure system with steel claws (nails), without belt for pieces feeding into processing. This feeding system, installed at the both sides if machine, very strong and with 100% accuracy by special "feeding claws" keep and pass the pieces through all working units. Exact this patented feeding system establish the highest quality of production.

Left sides of ASTRA machines bed plates are fixed, and the right sides are movable. The replacement of the right side is produced by special screw ball-bearing motorized mechanism with its own automatic lubrification system.

Main technical characters of ASTRA machines:

- min-max length of proceeding pieces: 200-1700(2500, 3200) mm;

- max width of proceeding pieces: 150(250) mm;

- max thickness of proceeding pieces: 85 mm;

- continuously adjustable feeding speed: 8-32 m/min.