CUSTOMIZED SAWMILL LINES A.Costa Righi

Code equipment: Customize Sawmill Lines EN

Short description

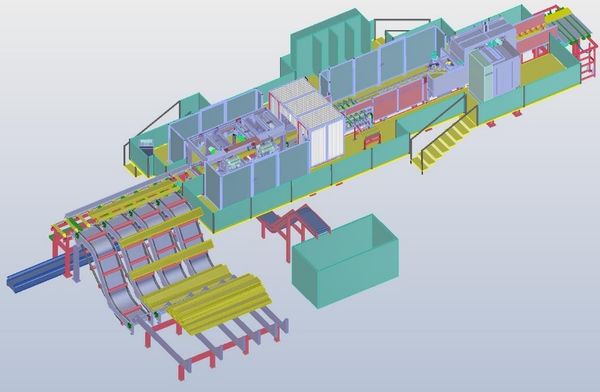

Sawmilling Lines for log / prisms processing, A.Costa special and/or standard Lines, high productive and most effective.

Customized automatic complete Lines for sawmill suitable for processing logs up to a maximum diameter of 450 mm, to obtain the trimming boards or elements for building, woodworking, beams and packaging (pallet production).

A.Costa Righi can develop and developing Sawmill Lines strictly for exclusive needs of each Client. A special feature of such Lines is the possibility to freely configure Line composition according to the types of work demanded for Client to be carried out.

Customized automatic complete Lines may be constructed in technology of logs processing with side logs solid wood wase, or base on the technologies without any solid wood wastes: Canter-ripsaw technologies or on the base of Canter-Profiling technology - complete wasteless sawmill technology, when round logs (prisms) "in one pass" are transformed into: trimming boards/beams + technological chips + clean sawdust. Where the technological chips are produced strictly adequate to the DINs (standards) for next steps of its processing into, for example, paper and carton, panel production, chemistry and so on.

The clean sawdust, for example - very suitable material for pellets production at second stage.

Customized automatic complete Lines of A.Costa Righi production usually have very high productivity and can proceed automatically till 7-10 ( and more) sorted round logs per minute.

A.Costa Righi can develop and developing Sawmill Lines strictly for exclusive needs of each Client. A special feature of such Lines is the possibility to freely configure Line composition according to the types of work demanded for Client to be carried out.

Customized automatic complete Lines may be constructed in technology of logs processing with side logs solid wood wase, or base on the technologies without any solid wood wastes: Canter-ripsaw technologies or on the base of Canter-Profiling technology - complete wasteless sawmill technology, when round logs (prisms) "in one pass" are transformed into: trimming boards/beams + technological chips + clean sawdust. Where the technological chips are produced strictly adequate to the DINs (standards) for next steps of its processing into, for example, paper and carton, panel production, chemistry and so on.

The clean sawdust, for example - very suitable material for pellets production at second stage.

Customized automatic complete Lines of A.Costa Righi production usually have very high productivity and can proceed automatically till 7-10 ( and more) sorted round logs per minute.