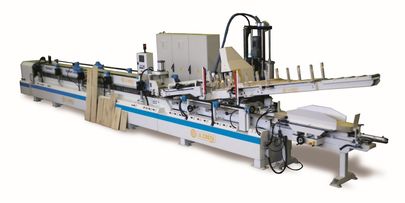

Continuous presses

KONTACT

Code equipment: KONTACT EN

Short description

Machines for continuous pressing of multi-(2-3) layer parquet boards KONTACT. Models for different dimensions, for different technology, different types of glue application.

Continuous press KONTACT - complete automatic machine for gluing and continuous pressing of 2- or/and 3-layer engineered parquet, supplied in three different versions depending on the maximum width of the lamellas.

The machine is covered by patents that make it unique in the world. Thanks to a press equipped with independent chromed wheels with separate pressure, that guarantee perfect gluing even with possible big enough variation of lamellas thickness.

The KONTACT machine is able to produce both as parquet with fixed lengths and parquet with random lengths. Machine proceed in "non-stop" mode. Machine can proceed in single one row and up till the complete production with five rows at the same time depending on the width of the lamellas.

Due to the use of PUR (polyurethane glue - hot-melt, or two components, neither glue catching for polimerization the rest humidity from using materials) the gluing of pre-finished parquet becomes very safe, reliable connected and not subject damages or deformations due to different environmental conditions.

With PUR glue application each produced parquet boards can be immediately and safely proceeds at next steps of operations without any problems, for example, it can be immediately after pressing profiled and squared in the immediatelly after installed processind Lines.

The KONTACT produced in three main modifications depend of the width of the machine working space:

- KONTACT-K 220 for parquet boards production with max width in 220 mm, such machine can produce till 1500 m3 parquet in one shaft;

- KONTACT-K 320 for parquet boards production with max width in 320 mm, such machine can produce 2100 m3 in one shaft;

- KONTACT-K 450 for parquet boards production with max width in 450 mm, such machine can produce 2700 m3 and more in one shaft.

All upper pointed machines has modification depend of number of rows of outfeed production.

Thus,

- KONTACT-K 220 has modifications to work in one (55-216 mm) row and/or in two (55-108 mm) rows;

- KONTACT-K 320 has modifications to work in 1 (55-316 mm) or 2 (55-156 mm) or 3 (55-103 mm) rows;

- KONTACT-K 450 has modifications to work in 1-2-3-4-5 rows consequently in width from 55 mm per each row.

All types of KONTACT presses can produce the parquet boards with FIXED (selected for this moment) or RANDOM length.

Also exist modification can proceed as with FIXED and with RANDOM length in the same one machine.

The machine is covered by patents that make it unique in the world. Thanks to a press equipped with independent chromed wheels with separate pressure, that guarantee perfect gluing even with possible big enough variation of lamellas thickness.

The KONTACT machine is able to produce both as parquet with fixed lengths and parquet with random lengths. Machine proceed in "non-stop" mode. Machine can proceed in single one row and up till the complete production with five rows at the same time depending on the width of the lamellas.

Due to the use of PUR (polyurethane glue - hot-melt, or two components, neither glue catching for polimerization the rest humidity from using materials) the gluing of pre-finished parquet becomes very safe, reliable connected and not subject damages or deformations due to different environmental conditions.

With PUR glue application each produced parquet boards can be immediately and safely proceeds at next steps of operations without any problems, for example, it can be immediately after pressing profiled and squared in the immediatelly after installed processind Lines.

The KONTACT produced in three main modifications depend of the width of the machine working space:

- KONTACT-K 220 for parquet boards production with max width in 220 mm, such machine can produce till 1500 m3 parquet in one shaft;

- KONTACT-K 320 for parquet boards production with max width in 320 mm, such machine can produce 2100 m3 in one shaft;

- KONTACT-K 450 for parquet boards production with max width in 450 mm, such machine can produce 2700 m3 and more in one shaft.

All upper pointed machines has modification depend of number of rows of outfeed production.

Thus,

- KONTACT-K 220 has modifications to work in one (55-216 mm) row and/or in two (55-108 mm) rows;

- KONTACT-K 320 has modifications to work in 1 (55-316 mm) or 2 (55-156 mm) or 3 (55-103 mm) rows;

- KONTACT-K 450 has modifications to work in 1-2-3-4-5 rows consequently in width from 55 mm per each row.

All types of KONTACT presses can produce the parquet boards with FIXED (selected for this moment) or RANDOM length.

Also exist modification can proceed as with FIXED and with RANDOM length in the same one machine.